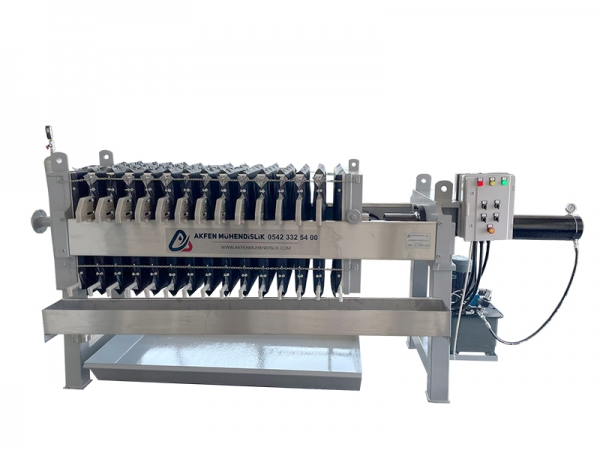

About the Filter Press

Filter Press has been used for years at sludge dewatering, oil dewatering areas. It is preferred in many applications as it is a highly efficient machine used to filter sludge, oil, and similar substances

The filter press machine is a special equipment that operates with the sense of separating solid and liquid phases, usually used in sludge dewatering, oil dewatering (reducing waste volume, reducing the amount of water in the product) or filtration applications.

The slurry, transferred by the pump, inside the Filter Press plates is filtered through the fabric, by leaving the solid materials in the spaces between the plates as the pressure rises.

At the filter press outlet, the filter press cake in the solid phase and the filtrate in the liquid phase emerge. The filtration process is intermittent, the system is opened as the plates are filled and the filter press cake is cleaned. Then theprocess is repeated.

The advantages of filter press compared to other dewatering and filtration equipment can be listed as below:

- High yield of sludge dewatering and oil dewatering

- Need for maintenance is little for filter presses

- Easy to run.

- Compatible with automation.

- Provides high suspended solids removal.

- Has a solid and durable structure.

- Initial investment and operating expenses are low

- Storage, transportation and disposal costs of the resulting cake are low.

- Increasing capacity or decreasing the capacity process can be easily modified on demand.

- The resulting cake concentration is entirely independent of the concentration of feeding waste.

Working principle of Filter Press

The solid-liquid mixture is transferred to the filter press with the help of a high pressure pump. The solid-liquid mixture is filtered by filter fabric covered on the filter press plates and the solid particles are collected between the filter plates. The liquid formed as a result of filtration is taken out of the equipment.

Filter press plates compressed with high pressure and the their fabrics should be fed with pressure pumps.

Solids gathered between filter press plates should be disposed by opening the plates and cleaning the substances between them.

Properties

- The high-pressure filter press will greatly shorten the entire filtration cycle.

- The membrane filter press adopts TPE and the maximum squeezing pressure can reach 2.5MPa, which will greatly reduce moisture content, save drying costs and increase production efficiency.

- It can reduce operation power consumption.

- In late filtration, the flow will be low and the pressure will be high.

- The membrane plate uses rubber or TPE.

It has many advantages: high strength, high squeezing pressure, high use and durableness

General fields of usage of the filter

Filter press equipment is generally used as sludge dewatering equipment in wastewater treatment facilities. Besides it is used for solid-liquid separation in many industrial processes.

- Oil Filter press

- Wastewater treatment filter press

- Sludge dewatering filter press

- Solid liquid separation filter press

- Liquid fertilizer filter press

- Chemical filter press

- Recycling filter press

- Dye bath filter press

- Drug filter press

- Mine filter press

- Recycling filter press

- Oil refining filter press

- Agriculture filter press

- Metalworking filter press

- Beverage filter press

filter press, sludge dewatering, filter press machine, sludge filter, oil filter press, manufacturing of filter press, oil dewatering, filter press sludge dewatering, filter press plate, filter press machine, filter press plate, filter press equipment, filter press second hand, filter press prices, filter press price for sale, filter press manufacturers, automatic filter press

|

PLATE DIMENSIONS (mm) |

250X250 |

400X400 |

500X500 |

630X630 |

Ø 800 |

800X800 |

1000X1000 |

|

|

CAKE VOLUMES |

0,8 |

2,5 |

5,50 |

8,50 |

13,0 |

16,0 |

24,0 |

|

|

PLATE QUANTITY |

5 |

4,0 |

12,5 |

27,5 |

42,5 |

65,0 |

80,0 |

120,0 |

|

10 |

8,0 |

25,0 |

55,0 |

85,0 |

130,0 |

160,0 |

240,0 |

|

|

15 |

12,0 |

37,5 |

82,5 |

127,5 |

195,0 |

240,0 |

360,0 |

|

|

20 |

16,0 |

50,0 |

110,0 |

170,0 |

260,0 |

320,0 |

480,0 |

|

|

25 |

20,0 |

62,5 |

137,5 |

212,5 |

325,0 |

400,0 |

600,0 |

|

|

30 |

24,0 |

75,0 |

165,0 |

255,0 |

390,0 |

480,0 |

720,0 |

|

|

35 |

28,0 |

87,5 |

192,5 |

297,5 |

455,0 |

560,0 |

840,0 |

|

|

40 |

32,0 |

100,0 |

220,0 |

340,0 |

520,0 |

640,0 |

960,0 |

|

|

45 |

|

247,5 |

382,5 |

585,0 |

720,0 |

1080,0 |

||

|

50 |

275,0 |

425,5 |

650,0 |

800,0 |

1200,0 |

|||

|

55 |

302,5 |

467,5 |

715,0 |

880,0 |

1320,0 |

|||

|

60 |

|

510,0 |

780,0 |

960,0 |

1440,0 |

|||

|

70 |

|

910,0 |

1120,0 |

1680,0 |

||||

|

80 |

1040,0 |

1280,0 |

1920,0 |

|||||

|

90 |

1170,0 |

1440,0 |

2160,0 |

|||||

|

100 |

1300,0 |

1600,0 |

2400,0 |

|||||